When you spend money on a nice new phone, one of the first things you do (if you’re smart) is get a case to protect it. Yale professor Jan Schroers, a specialist in materials science and mechanical engineering, is seeing to it that the next generation of smartphone cases is super tough and durable. Schroers works with Bulk Metallic Glasses, or BMGs. These ultra-strong but lightweight alloys are created by cooling molten metal incredibly quickly so that the typical crystalline structure of solid metal can’t form. BMGs, also known as amorphous metals, have an atomic structure that is closer to that of glass, but they are far sturdier.

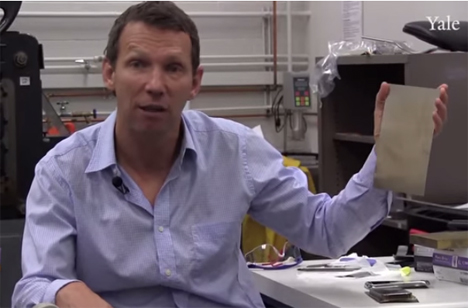

BMGs have been around since at least 1960, but until now researchers have had trouble figuring out just how to shape them for consumer use. Professor Schroers has developed a technique for forming them that involves shaping the alloys while they are in their supercooled liquid state. He uses this method, called thermoplastic forming, to create sheets of BMGs. Once the alloys are in sheet form, they can be shaped by a blow-molding process similar to that used to mold plastics.

Schroers has his eye on the consumer electronics market for the technology, to which Yale owns the rights. He has licensed those rights to create a line of ultra-durable, lightweight phone cases. They will be scratch-resistant and roughly 50 times harder than plastic. One of the main benefits of using BMGs is that buttons can be built right into the cases, opening up the possibility to make the next generation of smartphone cases waterproof as well as almost indestructible.