Developed by a trio of physics and engineering students at the University of British Columbia, this all-in-one recycler and printer grinds up waste plastics and melts them into usable filament for 3D printing.

The ProtoCycler from ReDeTec (Renewable Design Technology) is not the first reuse-oriented printer design but it combines the best elements of what is generally found separately – products that grind the plastic or melt it or extrude it – for faster and all-in-one use.

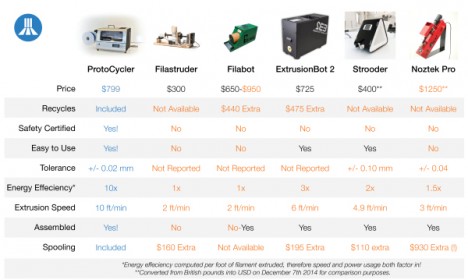

Taking anything from old plastic toys or soda bottles, it can turn trash into fresh filament at a record rate of ten feet per minute (making it the fastest extruder publicly for sale). Its materials are cheap as well – free, of course, if you generate them from your own plastic waste, but also only $5 per spool if made from the company’s plastic pellets (about 1/6 the cost of a typical filament loop).

The system can be pre-ordered for around $700, making it not the absolute cheapest desktop 3D printer out there but certainly a competitive option for those getting started with 3D printing or looking to save on material costs in the longer term (not to mention the environmental benefits).