With a few notable exceptions, just about all 3D printing up to this point has been done with plastic as a base material. A collaboration between MIT’s Mediated Matter Group, MIT’s Department of Mechanical Engineering and MIT’s Glass Lab has led to a pretty exciting advancement: 3D printing with molten glass.

The group calls their process G3DP. It involves an upper cartridge acting as a kiln at up to 1900 degrees Fahrenheit. The lower chamber anneals the molten glass, allowing it to cool slowly, letting the newly-printed structure harden. The team figured out that by precisely adjusting the orientation and thickness of the optically transparent glass, they can closely control the light transmission, reflection, and refraction qualities of the finished objects.

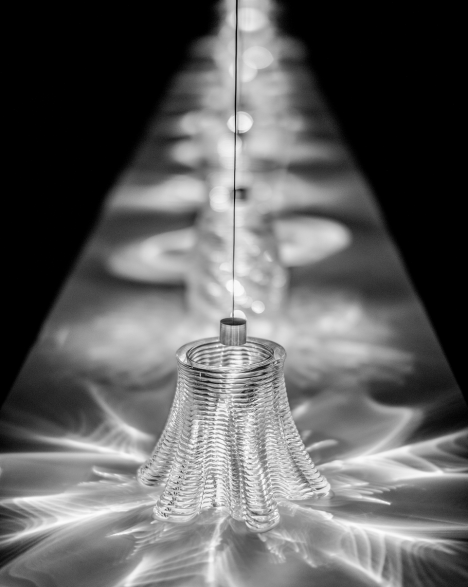

That may sound a little like mumbo-jumbo, and the video only seems to focus on the (admittedly very impressive) artistic value of the G3DP method. But in simpler terms, it means that this method might help us make higher-quality, less-expensive fiber optics in the near future. It could even be used as a simpler method of making eyeglass lenses – and the decorative possibilities are still a pretty big part of the G3DP method’s appeal, of course. Just imagine these gorgeous bespoke light fixtures all throughout your house!