The past two decades have brought about some incredible – and very expensive – advances in prosthetic limb technology. A prosthetic leg can now contain microprocessors, gyroscopes, and hydraulics to give the amputee a completely natural gait. In India and other developing nations, having a leg amputated usually means a lifetime with a stiff, unmoving prosthetic. MIT associate professor of mechanical engineering Amos Winter wants to bring a low-tech solution to people in developing countries who don’t have $50,000 to spend on a top-of-the-line leg.

Winter and his associates published a paper detailing their research on the ideal torque that a prosthetic leg should produce in order to replicate the gait of a natural knee. Working off of that research, the team was able to build a prototype of a working prosthetic leg that uses simple elements like springs and dampers instead of high-tech electronic components.

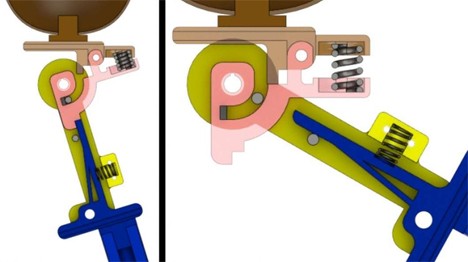

Their low-tech prototype uses a spring to slightly bend the “knee” as the leg moves; two dampers stop the leg from swinging backward and slow it down during its forward movement just before the heel hits the ground. Using this simple system, the prosthetic leg allows for a much more natural gait than the typical non-dynamic prosthetic leg. The researchers have begun testing their invention with above-the-knee amputees in India and hope that, once refined, their prosthesis will cost only a few hundred dollars.